Comau makes innovative assembly lines for HYCET

A technologically advanced production line makes it possible to meet stringent requirements for precision and product quality, while ensuring better adaptability and efficiency and reducing production costs.

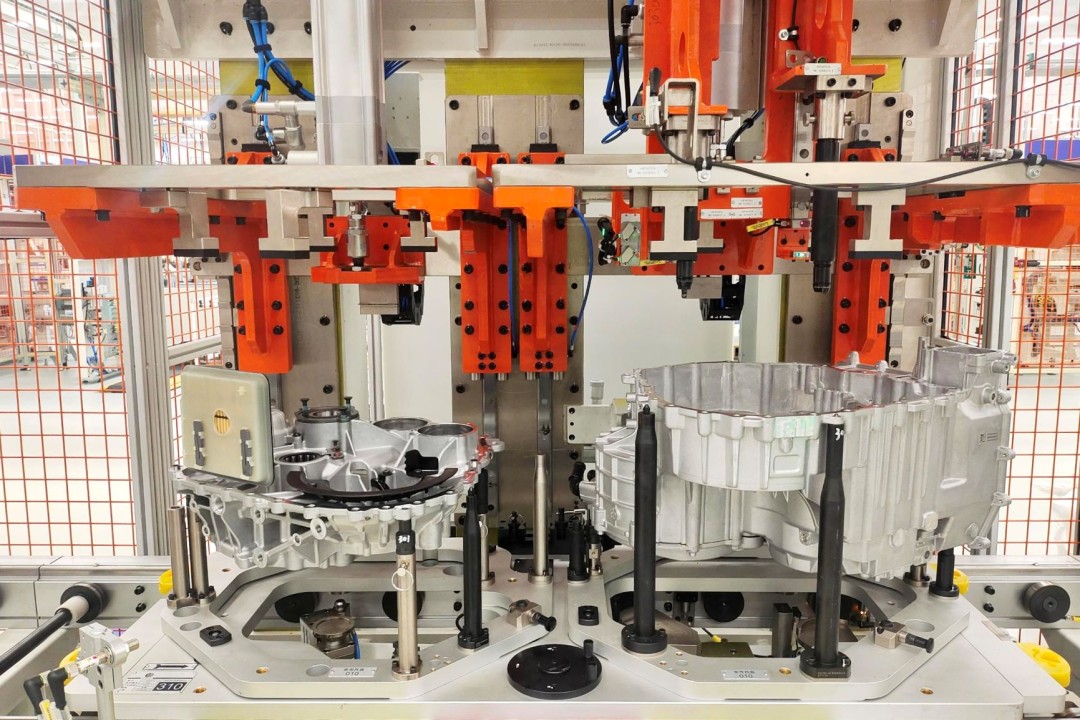

Comau developed all the necessary components for the fabrication and installation of a high-volume automated assembly line for HYCET, a subsidiary of Great Wall Motor and a leading manufacturer of DHT (Dedicated Hybrid Transmission) technology.

The Italian company, based in Piedmont, was entirely responsible for all the components needed to make the project a reality, including the assembly lines for electric motors, gears and crankshafts, main assembly lines and test lines. The system also includes complex processes that ensure complete assembly from individual components to fully functional units.

The result is the high-speed L.E.M.O.N. hybrid DHT manufacturing solution capable of both meeting HYCET's stringent requirements for precision and product quality, and ensuring improved adaptability and efficiency, while allowing reduced production costs for future DHT product upgrades.

In fact, the Comau-designed production line can be easily customized to meet different market needs and consists of a next-generation transmission system that allows the simultaneous use of gasoline engines and electric motors, enabling efficient power sharing between them.

Comau also used a process-integrated overall station design to ensure stability and quality along the entire production line, with an equipment availability rate of 90 percent. A Manufacturing Execution System (MES) enables HYCET to optimize line management and scheduling. Finally, key process parameters such as power and displacement are continuously monitored to ensure quality control throughout the production process and support subsequent data traceability.

To meet the customer's large-scale production goals, Comau's complete solution involves a total of 12 robots on 6 lines to provide an annual production capacity of 150,000 units per line, with a cycle time of less than 2 minutes.

Related news

Last News

RSA at Cybertech Europe 2024

Alaa Abdul Nabi, Vice President, Sales International at RSA presents the innovations the vendor brings to Cybertech as part of a passwordless vision for…

Italian Security Awards 2024: G11 Media honours the best of Italian cybersecurity

G11 Media's SecurityOpenLab magazine rewards excellence in cybersecurity: the best vendors based on user votes

How Austria is making its AI ecosystem grow

Always keeping an European perspective, Austria has developed a thriving AI ecosystem that now can attract talents and companies from other countries

Sparkle and Telsy test Quantum Key Distribution in practice

Successfully completing a Proof of Concept implementation in Athens, the two Italian companies prove that QKD can be easily implemented also in pre-existing…

Most read

Planview Enters 2026 with New Leadership and Continued AI Innovation

Planview®, the leading platform for Strategic Portfolio Management (SPM) and Digital Product Development (DPD), today announced strong 2025 momentum,…

Technology Innovation Institute and World Economic Forum Announce ‘Abu…

The Technology Innovation Institute (TII), the applied research arm of Abu Dhabi’s Advanced Technology Research Council (ATRC), and the World Economic…

Pricefx Enters 2026 With Record Momentum and Breakthrough AI Adoption

#AI--Pricefx, the global leader in AI-powered, cloud-native pricing software, today announced strong 2025 results, marking a year of sustained growth,…

Yelp Announces its 2026 Top 100 Places to Eat in the United States

Yelp, the company that connects people with great local businesses, today announced its 13th annual list of the Top 100 Places to Eat in the U.S., highlighting…